Manufacturers operate in a highly competitive market where speed, accuracy, and efficiency define success. Traditional shop floors often struggle with fragmented systems, manual processes, and limited visibility. These challenges directly affect throughput and productivity.

The ERP manufacturing module addresses these problems by digitizing the shop floor. It integrates production planning, inventory, quality, and workforce management into a single platform. This digitization enables companies to track operations in real time, reduce downtime, and optimize throughput. In this blog, we explore how ERP transforms shop floor operations and drives manufacturing excellence.

Table of Contents

ToggleWhy Digitizing the Shop Floor Matters

Modern manufacturing depends on accurate data and seamless coordination. Manual shop floor processes cannot deliver the visibility and agility required today.

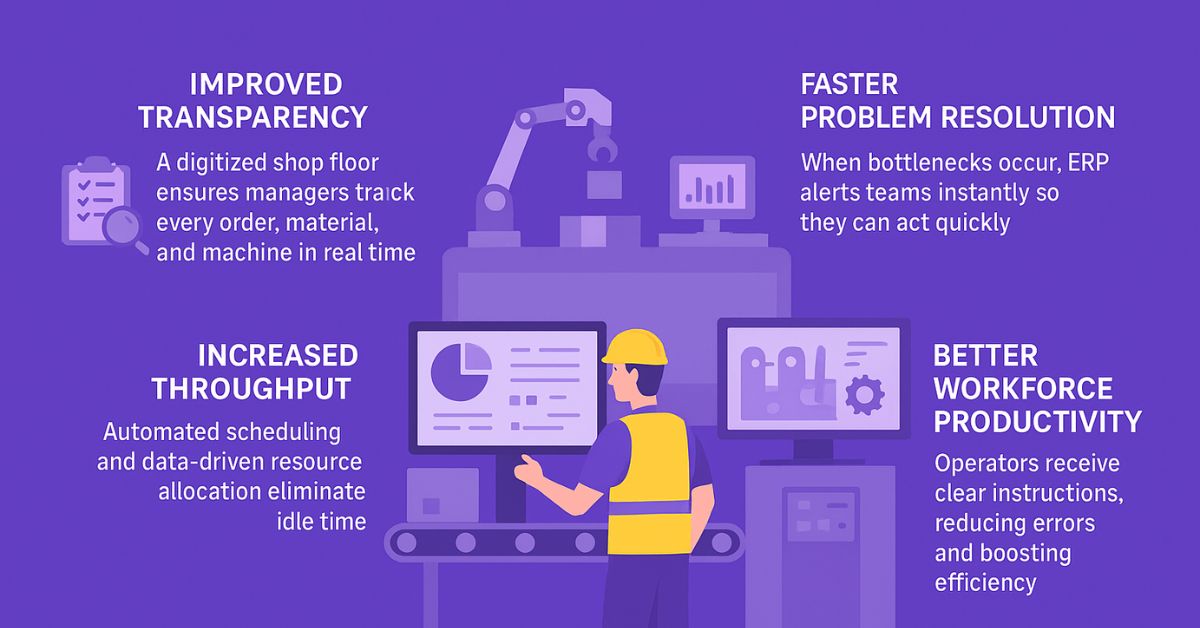

1- Improved transparency: A digitized shop floor ensures managers track every order, material, and machine in real time.

2- Faster problem resolution: When bottlenecks occur, ERP alerts teams instantly so they can act quickly.

3- Increased throughput: Automated scheduling and data-driven resource allocation eliminate idle time.

4- Better workforce productivity: Operators receive clear instructions, reducing errors and boosting efficiency.

Digitization through the ERP manufacturing module gives companies the control they need to balance costs, quality, and speed effectively.

Core Features of the ERP Manufacturing Module

The ERP manufacturing module is designed to centralize and streamline shop floor operations. Its features ensure a connected, data-driven environment.

1- Work order management: Automates creation, scheduling, and tracking of production orders, reducing paperwork.

2- Real-time machine monitoring: Integrates with IoT devices to track uptime, downtime, and machine performance.

3- Inventory synchronization: Links raw material consumption and finished goods reporting to inventory levels.

4- Quality management: Embeds quality checks into workflows, reducing rework and waste.

Together, these features enable manufacturers to digitize the shop floor for better throughput and sustained competitiveness.

Optimizing Throughput with ERP Tools

Throughput measures how efficiently a factory converts raw materials into finished goods. ERP modules directly impact this metric.

1- Finite capacity scheduling: Plans production based on realistic machine and labor availability.

2- Bottleneck identification: ERP highlights slow processes that affect the entire production flow.

3- Automated routing: Directs jobs to the right machine or workstation, reducing delays.

4- Performance dashboards: Provides managers with live metrics on throughput, scrap, and cycle times.

With these tools, the ERP manufacturing module helps factories improve throughput without compromising quality.

Reducing Downtime Through Digitization

Downtime is one of the biggest barriers to manufacturing efficiency. ERP systems help minimize both planned and unplanned downtime.

1- Predictive maintenance: Sensors feed data into ERP, allowing preventive maintenance before breakdowns occur.

2- Maintenance scheduling: Aligns machine servicing with low-demand periods to avoid production disruption.

3- Resource readiness: Ensures spare parts, tools, and technicians are available for repairs.

4- Downtime reporting: Tracks causes of downtime, enabling teams to prevent repeat issues.

By digitizing the shop floor with ERP, manufacturers move from reactive to proactive maintenance, directly improving equipment utilization.

Workforce Empowerment with ERP

The workforce plays a vital role in ensuring efficiency. ERP provides operators, supervisors, and managers with tools to perform better.

1- Role-based dashboards: Operators view their tasks, while managers access shop-wide performance data.

2- Digital instructions: Work orders include clear, step-by-step instructions, reducing errors.

3- Mobile access: Employees can access ERP data on handheld devices, increasing flexibility.

4- Performance monitoring: Tracks operator productivity, enabling targeted training and support.

Empowering the workforce with ERP manufacturing module tools ensures better alignment and higher productivity across the shop floor.

Data Accuracy and Real-Time Visibility

Accurate and timely data is the backbone of manufacturing efficiency. The ERP manufacturing module ensures this across operations.

1- Centralized data: Integrates production, inventory, and financial data into one system.

2- Real-time updates: Provides immediate insights into material consumption, work progress, and order status.

3- Error reduction: Minimizes manual entry by automating data capture from machines and operators.

4- Compliance reporting: Ensures accurate records for audits and regulatory requirements.

With clean, reliable data, decision-makers can optimize throughput and eliminate inefficiencies.

Scaling Production with ERP

Growth in demand or expansion into new markets requires scalable systems. The ERP manufacturing module enables manufacturers to handle complexity.

1- Multi-plant support: Manages operations across multiple factories from a single system.

2- Flexible production models: Supports make-to-order, make-to-stock, and hybrid approaches.

3- Advanced analytics: Uses historical and predictive data to forecast production requirements.

4- Global compliance: Ensures standardized reporting across international locations.

ERP gives companies the agility to scale production while maintaining high throughput and low costs.

Best Practices for Implementing ERP on the Shop Floor

To maximize value, manufacturers should follow proven best practices when adopting ERP for shop floor digitization.

1- Define clear objectives: Focus on goals like throughput improvement, downtime reduction, or data accuracy.

2- Engage shop floor teams: Involve operators and supervisors in planning and testing phases.

3- Invest in training: Provide hands-on ERP training to improve adoption and confidence.

4- Start small and scale: Pilot ERP in one line or plant before rolling it out company-wide.

These practices ensure that ERP implementation for manufacturing modules delivers long-term results.

Conclusion

The ERP manufacturing module is more than a back-office tool. It digitizes the shop floor, enabling manufacturers to improve throughput, reduce downtime, and empower their workforce. By providing real-time visibility, predictive maintenance, and scalable tools, ERP creates a connected and efficient factory environment.

Manufacturers that embrace ERP not only gain immediate operational improvements but also position themselves for long-term growth. In a competitive market, digitizing the shop floor with ERP is no longer optional, it is a strategic necessity for efficiency and profitability.